Cleanroom Processes and Equipment performance management, an interview with José Rodrigues – Facility Manager

August 4, 2022

José Pedro Rodrigues, Facility Manager, is currently a member of the Micro and Nanofabrication Facility at INL. Among his facility management responsibilities, José focuses on cleanroom processes and equipment performance management.

José joined INL in 2016 with already 19 years of significant industrial background. He worked for international semiconductor companies having roles in Operations, Equipment and Process Engineering departments. More recently, he worked in a Swiss MEMS and Sensors company as an Equipment Specialist.

He owns a degree in Industrial Engineering and Management from Instituto Politécnico do Porto, an MBA from Instituto Europeo de Posgrado de Madrid and a Master’s degree in Micro and Nanotechnology from University of Minho. And he is currently attending a PhD program in Chemical Engineering from Universidad de Vigo.

Can you tell us a bit about your path, your main area of work, and the importance of your work?

My career path was atypical, difficult, and uncommon compared to regular students and professionals. I started working before finishing my graduation. All my university studies were carried out in parallel with my professional career. I worked for about 20 years in the semiconductor and MEMS industry, developing different roles – from operations to equipment maintenance and process engineering until 2016 when I joined the Microfabrication and Exploratory Nanotechnology group as Research Engineer.

My career allowed me to work, in different countries such as Malaysia, Germany, and Switzerland, where I had the opportunity to get in touch with different cultures around the world. INL offers this multiculturality inside Portugal.

In 2020, I became Facility Manager at the INL Micro and Nano Fabrication Facility where my daily work scope is to offer and keep the facility available and in excellent conditions to be used, exploring the limits of the technology cutting-edge tools. In parallel, I am actively participating in the integration and execution of research and industrial projects.

Recently, I am working in collaboration with Universidad de Vigo and Universidad de Santiago de Compostela to research, develop, and fabricate devices with in-situ/operando capabilities for Transmission Electron Microscopy for energy applications.

The INL cleanroom facility offers micro-and nanofabrication solutions on substrates from 200-mm-diameter wafers down to a few mm in size, to both internal and external users. Can you please explain the open-access user facility and all the support the Micro and Nanofabrication Facility team offers?

The micro and nanofabrication facility is designed to allow open access to all users, whether internal or external, more or less experienced, so that they can develop their research projects with creativity and in safe conditions.

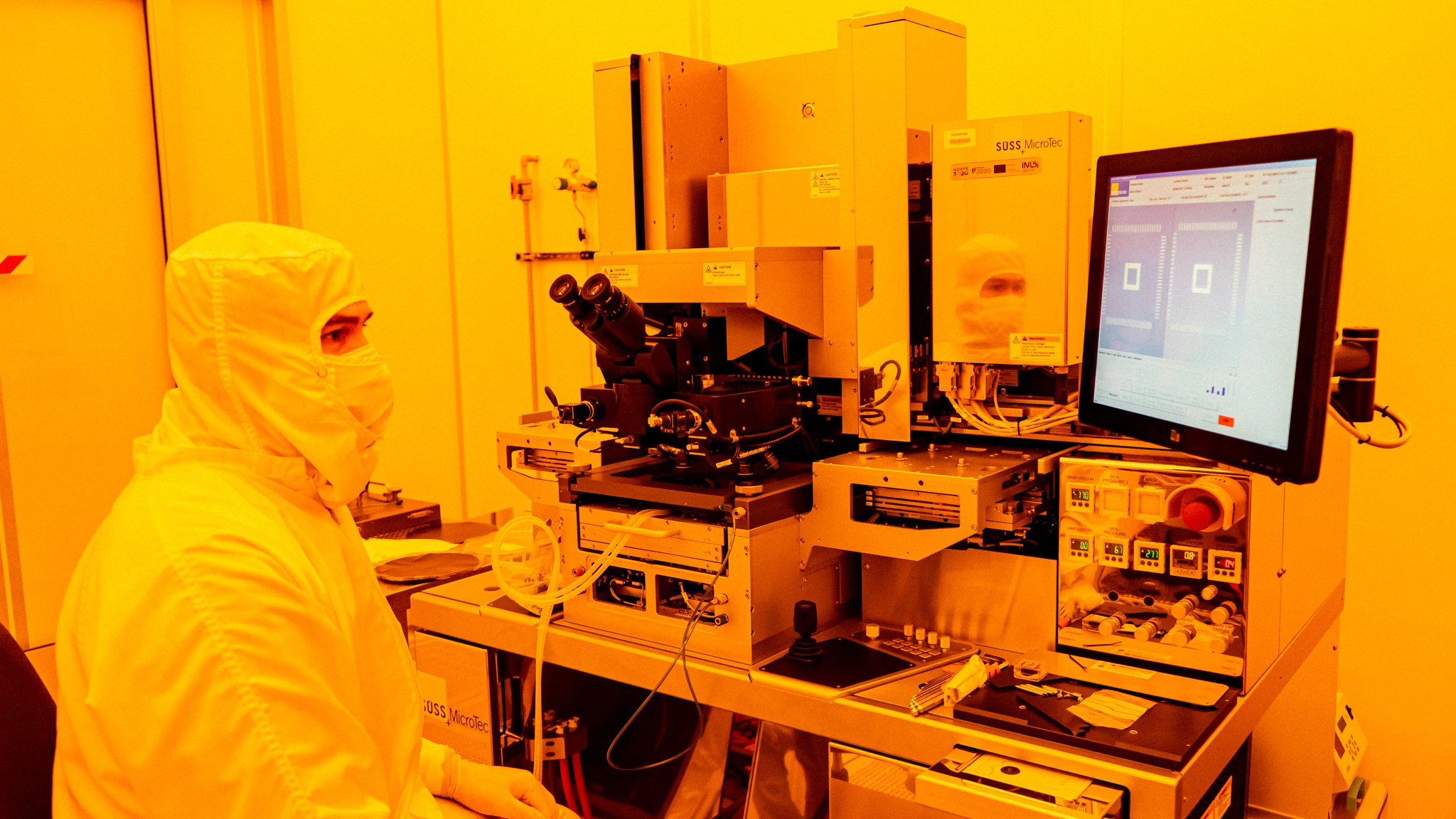

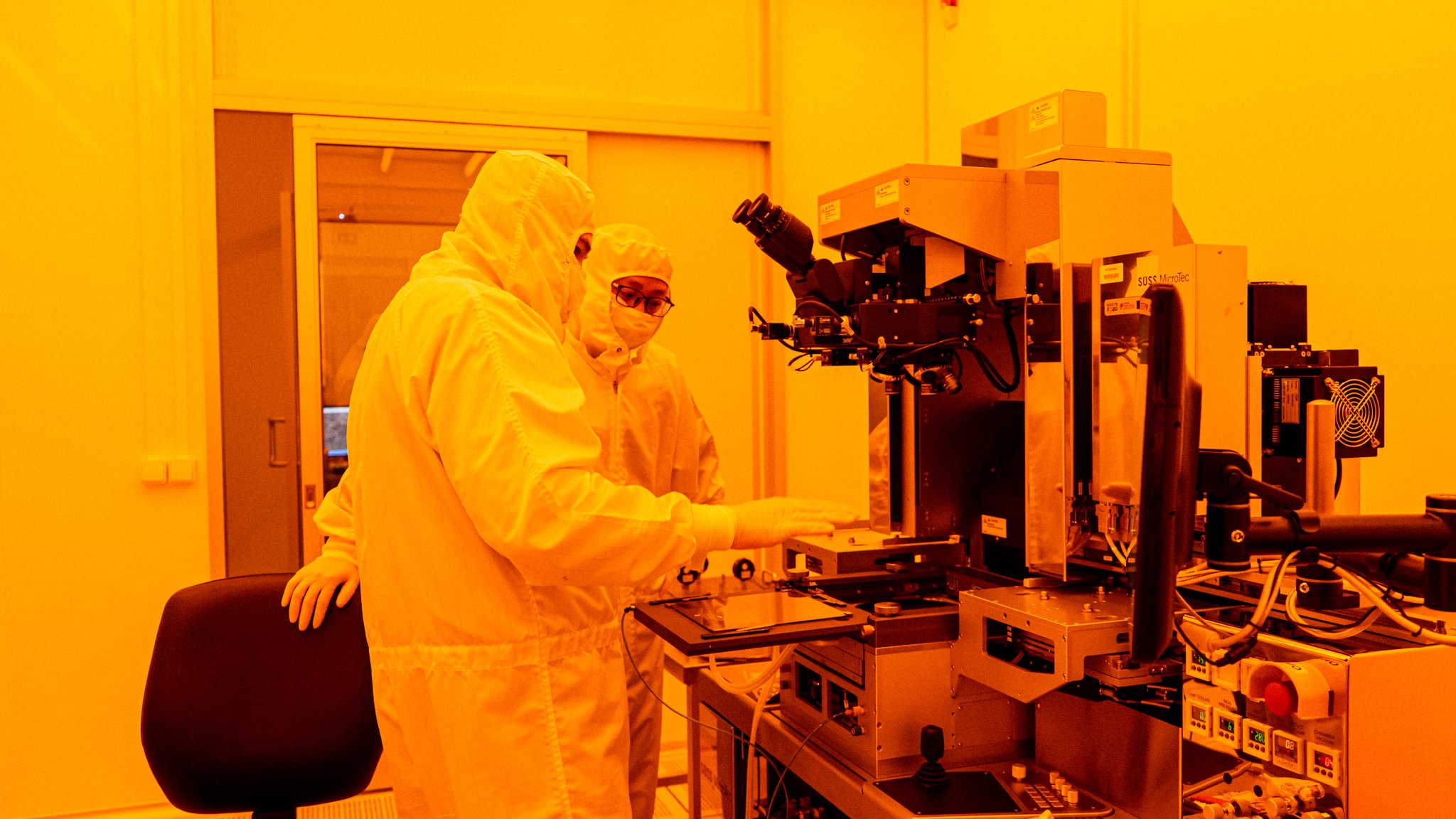

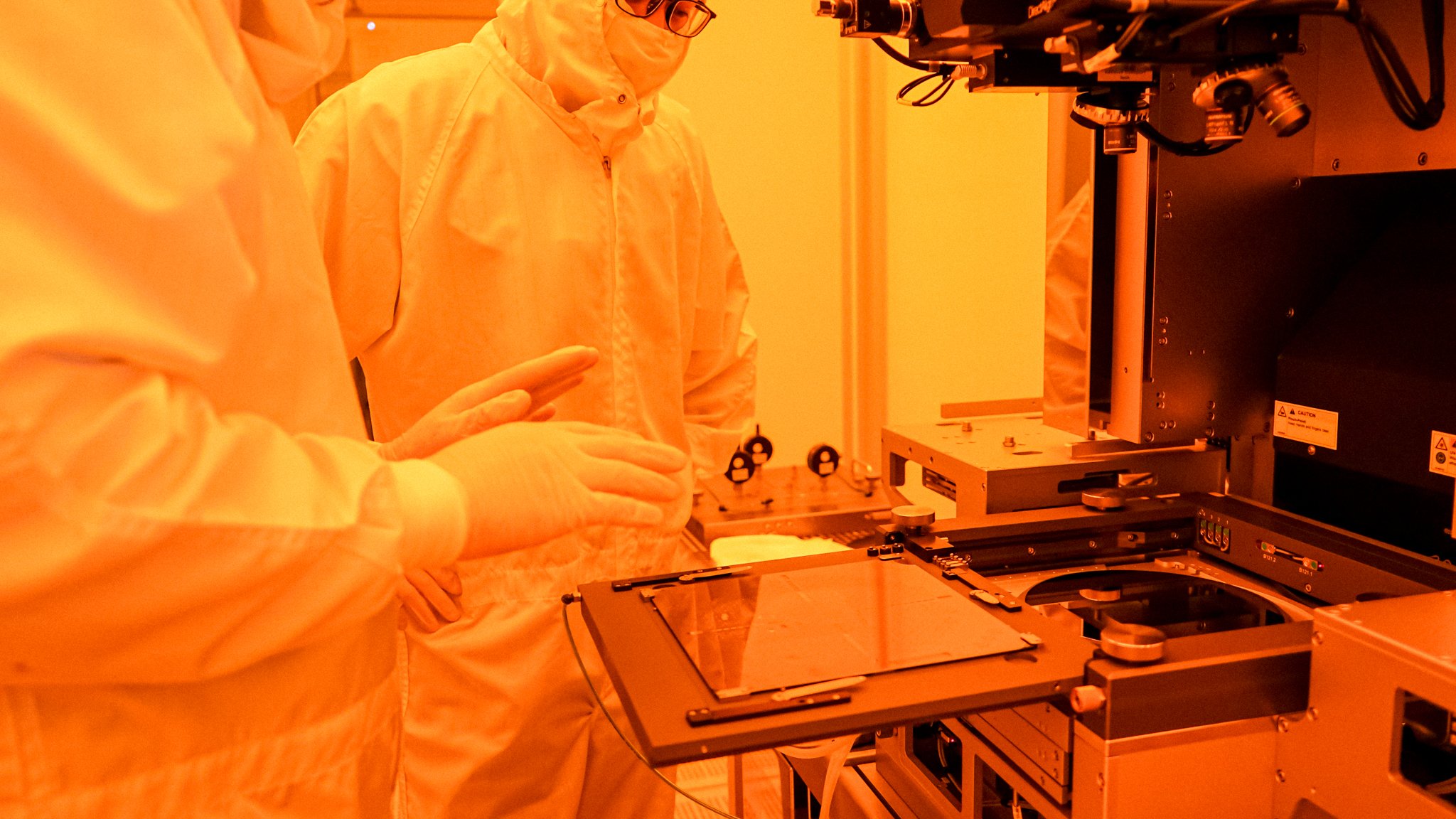

In approximately 1000m2 of cleanroom, you will find cutting-edge technology equipment in the area of micro and nanofabrication managed by a competent, experienced and trained team of engineers and scientists who will support you to achieve your goals.

Since the foundation of this facility, we have been continuously reinforcing the machinery park and developing techniques that have allowed us to meet the general needs of the hundreds of users who annually carry out their research and execute industrial projects with great technical relevance.

The cleanroom meets the standard of ISO 5 class, follows the ISO 9001:2015 and ISO 13485:2016 standards, and allows full support for the development of scientific projects in areas as diverse as M/NEMS, Spintronics, Solar Cells, Microfluidics, Photonics, Optics, and 2D materials (such as graphene and carbon nanotubes) and much more using different substrates like silicon, glass or polymeric ranging from 200 mm down to a few mm.

The facility team’s main functions are to maintain the facilities, train users, share knowledge, explore and advise on new approaches, and support the execution of the tasks that the users are aiming for. The user’s support starts from gowning and protective equipment to equipment, process setup and consumables. Our goal is to be users’ partners in their research path.

Any advice for students considering a career in science?

You should prepare yourself as best as possible. Science is as fascinating as it is challenging and hard work. Only people with a great capacity of work and resilience are capable of making a career in science. Prepare well and join the best institutions that can give you the right conditions to succeed.

Work, happiness, and success do not come alone. Science is teamwork and only the best teams win. INL has excellent conditions for doing science in Portugal, at the level of the best institutions in the world.

If you weren’t a Researcher, what would you be doing?

I’m especially touched by engineering challenges. I’m the happiest person putting my hands on the job and making it happen, I am more action than words. If I had to choose a different career, I think it would be in the field of architecture or landscape architecture. Not because I’m a good designer or a particularly creative person, but because I like to see things get out of my hands, to make them happen and see their impact on society and people’s lives.