Detecting food allergens with paper microfluidics and a smartphone

March 7, 2024

Every day, millions are at risk of falling ill due to undetected allergens or contaminants in their food. However, a groundbreaking solution may be on the horizon, as researchers investigate a game-changing technology to combat foodborne risks.

The Food Quality and Safety research group recently published a study describing a cutting-edge technology that provides faster, cheaper, and more reliable detection of allergens like β-lactoglobulin in our food.

Traditionally, detecting allergens in food products has been a complex and costly process. Current methods, including enzyme-linked immunosorbent assays (ELISA) and polymerase chain reaction (PCR), require specialised equipment and highly-trained personnel, making them difficult to use. INL researchers are contributing to reshaping the landscape of food safety with a new nanotechnology approach.

Their pioneering approach? Fluorescent carbon quantum dots combined with aptamers, which are short, single-stranded DNA or RNA molecules that can bind to specific target molecules with high affinity and specificity.

By leveraging the unique properties of carbon quantum dots and aptamers, the researchers have developed a highly sensitive and portable detection method for β-lactoglobulin, the primary allergenic whey protein found in cow’s milk.

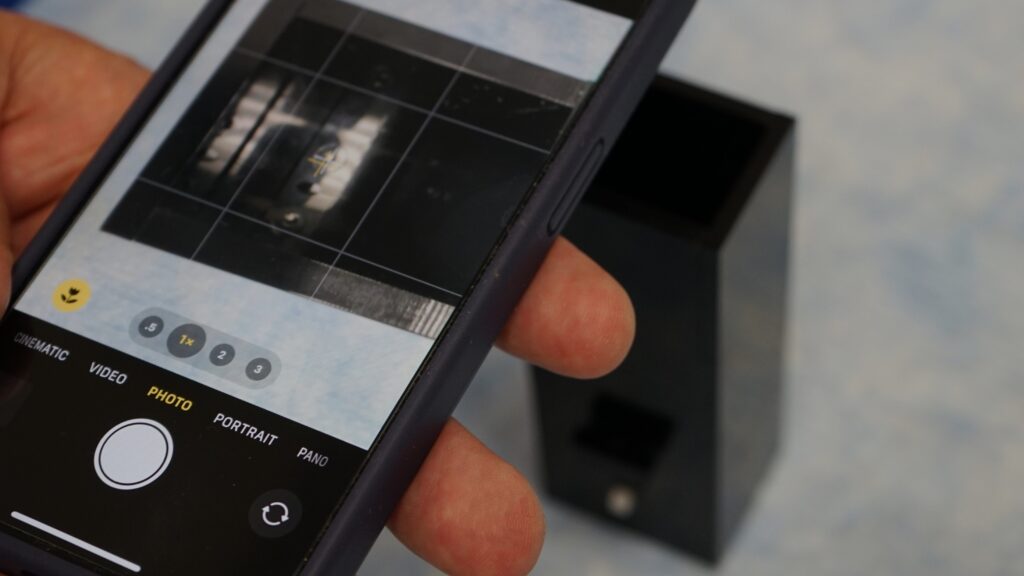

What sets this technology apart is its simplicity and effectiveness. The team has created a user-friendly platform that requires minimal sample preparation and no specialized equipment, using microfluidic paper-based analytical devices (µPADs). With just a smartphone equipped with a UV LED and dark housing, users can capture images and quantify the fluorescence response, enabling real-time analysis on-site and on the go.

To demonstrate the applicability of the µPAD, the team carried out the determination of β-lactoglobulin in crispy rice, cookies, and chocolate samples. The solid samples were free of milk content and were deliberately spiked with known amounts of skimmed milk to mimic the cross-contamination that could occur during food manufacturing. With a limit of detection as low as 0.6 ng/mL, this technology surpassed previous methodologies, offering high sensitivity and accuracy.

Imagine a world where food manufacturers, distributors, and consumers alike can easily identify and mitigate allergen risks, from the processing plant to the kitchen table. With the µPAD aptasensor developed by researchers at INL, University of Granada, and University of Santiago de Compostela, that vision is now becoming a reality. The developed sensor could have a significant impact on public health and consumer confidence, offering a vital tool to safeguard against the threat of foodborne illnesses.

For individuals with sensitivities, even trace amounts of allergens can trigger severe reactions. The µPAD developed by the Iberian consortium provides a more direct, simpler, portable, and low-cost tool to determine allergens in food samples.

This research study was funded by TITAN, by the European Union’s HORIZON EUROPE research and innovation programme under grant agreement No 101060739.

Text & Photography by Catarina Moura, Science Communication Officer